[ad_1]

Even Hollywood seen. Within the 2022 movie The Batman, directed by Matt Reeves, a Honda CB750 café racer ridden by Bruce Wayne, performed by Robert Pattinson, is fitted with Raysons’ 4-into-2 pipes and twin mufflers. Of crafting the system for the movie’s Honda, Ben explains, “That’s one thing that I’ll battle to prime. It was one of many hardest secrets and techniques that I’ve ever needed to hold. Particularly as a consequence of lockdowns which delayed filming by two years. However the reward was one thing that I can’t describe. Attending to see and listen to one thing I’ve made with my very own palms, on the cinema display screen. There’s a nice scene, the place Bruce Wayne is using by Gotham on his Honda café racer, with Nirvana taking part in within the background, and the digicam strapped to the rear shock, wanting on the silencer. That blew my thoughts. After which having the ability to purchase the identical bike and exhaust pipes in toy type, is one thing that just a little boy’s goals are manufactured from! It’s nonetheless one thing that hasn’t sunk in absolutely but.”

Coming from what might be thought-about one thing of a motorbike dynasty, Ben’s background is extraordinary, and it’s steeped in British bikes, racing and café racer historical past. His mother, Gail, was the daughter of Peter Lee. Peter was one in every of three co-owners of Unity Equipe of Rochdale, a widely known and extremely revered specialist store arrange within the late Nineteen Fifties promoting first British motorbike spares, and later café racer elements to the Ton-Up crowd and to severe racers. Whereas Peter wasn’t a racer himself, he sponsored a choose variety of native riders and sidecar groups and traveled the circuit in a Unity Equipe racing van to help their efforts. Ben’s dad, Ray Hardman, wasn’t raised round bikes. Nevertheless, Ray’s three brothers have been excited about them, and that set the tone for him.

“My dad’s older brother was into motocross and would typically enter into native races throughout the Seventies,” Ben says, and continues, “At which level, Barry Sheene was in all of the papers and my dad determined, as an alternative of being chased by the police on the general public roads, he would have a go at street racing as an alternative. He managed to purchase two outdated race bikes off a neighborhood bike store, who additionally gave him sponsorship racing a Triumph 500 in an Aermacchi body, and a Rudge 350 dash bike. He then signed himself as much as enter some basic races, aged 17. It was at this level that my dad began utilizing grandad’s store, Unity Equipe, to purchase his British spares. And that’s the place he seen my mum working. One night time on the town, he approached my mum, saying, ‘You’re the lady from the bike store,’ and the remaining is historical past.”

Peter constructed Ray a T350cc Manx Norton with unique Manx spares he’d purchased straight from the manufacturing facility through John Tickle. Moreover, Ray constructed his personal BSA B50 utilizing Unity parts and the store sponsored him to run it. These are a few of the fondest recollections Ben has of his upbringing, and he begins, “I at all times say, ‘I’m simply Ben, from Bacup,’ an bizarre lad from a really small bizarre city, within the northwest of England, in again nook of Lancashire. I grew up within the shadows of huge Victorian cotton mills that lined the valley bottoms and was blessed by giant expanses of moorlands and quarries, the place we might play out all day and discovered to experience our bikes. As a small boy, you don’t discover a lot of what’s occurring round you, and also you don’t understand how nice the individuals round you might be. I grew up surrounded by nice racing bikes and nice motorbike racers and by no means actually thought a lot of it. They have been simply bikes that my dad rode or raced towards. And the racers have been simply bizarre individuals like my dad, who had bizarre lives and bizarre day jobs. However one factor I didn’t understand till I acquired older, was how obsessed I used to be with bikes.”

Ray put Ben first on a Yamaha PW50. When Ben outgrew that, Ray gifted him a Yamaha TY80 for his eighth birthday. “We spent each weekend dad wasn’t racing within the native quarry, studying methods to trials experience, with plenty of assist from native specialists that my dad knew. Dad purchased a Fantic 125cc Skilled, so he might come out and experience with me, and two years later, when my youthful brother, Tommy, acquired to age eight, my dad determined it was time all of us had a change.” Ben took over his dad’s Fantic, whereas Ray purchased a Bultaco 340. The Yamaha TY80 was modified with a Honda C50 engine for Tommy, and the household rode collectively within the quarry for one brief 12 months. That’s when in 1997, at Olivers Mount, Ray, aged 37, died in a crash. Ben recollects, “I used to be 11 years outdated, and from that time on, I attempted my hardest to maintain myself within the bike scene, but it surely was so much tougher when your dad, your finest good friend, isn’t there to do it with you.” Ray’s ex-teammates helped hold the spirit alive for Ben and Tommy, persevering with to take them to races and getting them to assist pit for the workforce.

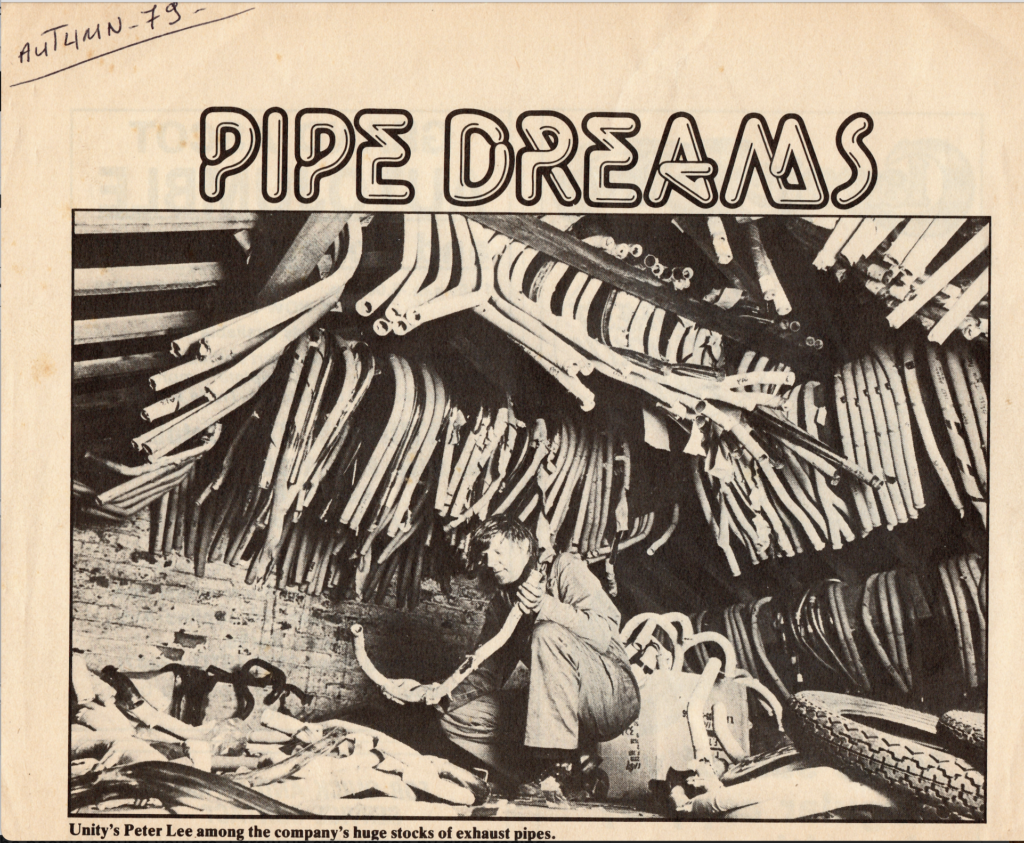

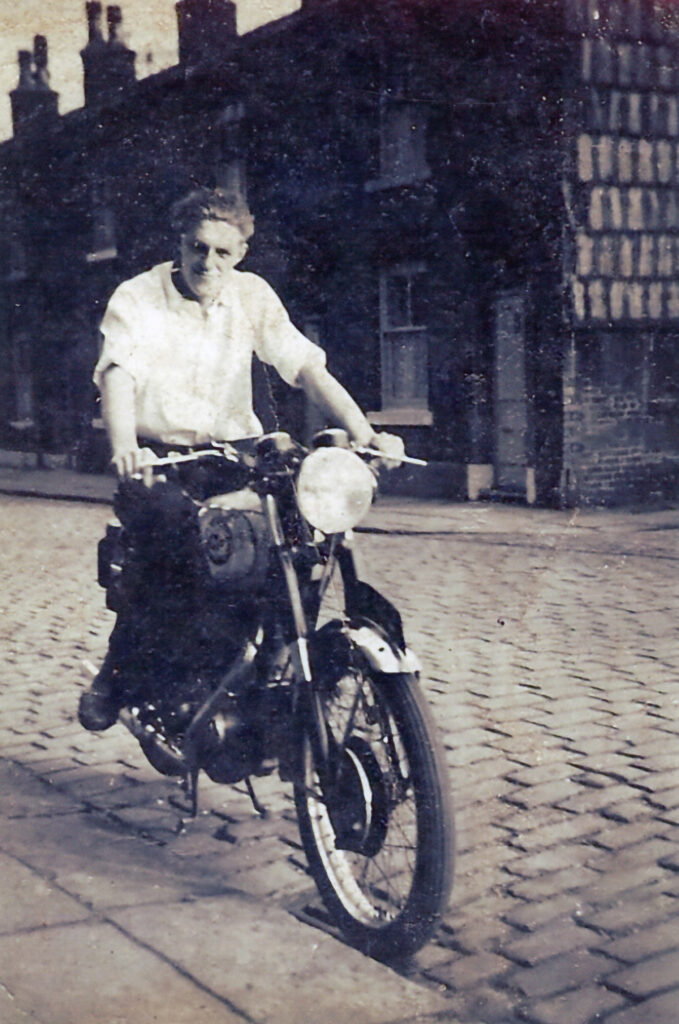

Simply how Raysons Exhaust took place is a long-ish story, but it surely all begins with Ben’s grandad, Peter. After working a number of different jobs, as a younger man Peter turned a blacksmith and in his early 20s had saved sufficient cash to purchase a BSA Gold Star as a commuter machine. He usually rode to work in Rochdale however was someday knocked off the BSA. That’s when, Ben says, “Grandad and his pals all used to make use of a neighborhood motorbike store for his or her spare elements. This store was run by John Newby. It was on this store, that the concept of a brand new greater store, was first thought up. The plan was to purchase the massive outdated CO-OP store within the subsequent city and switch it into a big British spares store. I believe the concept would have tied in with the overall decline of motorbike outlets within the U.Ok. My grandad, together with John Newby, who already owned the bike store, and one other good friend, Brian Topping (later changed by Bob Mainwaring), would be a part of forces and arrange a enterprise referred to as Unity Spares. It could specialise in British bike elements and would purchase inventory from different failing motorbike companies.” Ben’s grandad, Peter, labored the store full-time. Due to his blacksmithing expertise, Peter was additionally capable of create an unlimited vary of exhaust techniques, a lot so, that by the Seventies, the corporate was one of many largest suppliers of pipes within the U.Ok. Because the British spares market started to falter, nonetheless, a change in path noticed the companions re-brand as Unity Equipe, focusing extra on café racer elements. “Within the mid Seventies. they managed to accumulate the rights to the Manx Norton title, plus all of the instruments, spares and drawings off of Colin Seeley, who had purchased the title off Norton, offered it to John Tickle after which purchased it again once more,” Ben says. “By shopping for this iconic title, it meant that Unity might provide all of the elements wanted to construct a Norton primarily based café racer particular, and particularly the Triton bikes which Unity later turned well-known for.”

As Unity turned very nicely established within the early Eighties, Peter had much less time to create exhaust pipes and outsourced manufacturing to a Birmingham-based tube bender. This lasted till the craftsman making the pipes died – and Peter struggled to search out one other maker. Across the identical time, Ray misplaced his job at a big engineering firm and was unemployed. Desirous to deliver pipe bending and different elements manufacturing in-house, Peter and his enterprise companions began a brand new firm referred to as Uni-Bend Engineering, placing Ray in cost. They bought a lathe, mill, and mandrel tube bender. Ray discovered a store area to lease within the cellar of an outdated cotton mill. He would have been 24-years outdated, and Ben says with some mentorship from Peter, taught himself to weld and methods to bend tubes. “He rapidly acquired to grips with it, and with a gentle stream of orders to be offered by the store, Dad quickly made sufficient cash to purchase the shares owned by the store,” Ben explains. “And by the point I used to be born in 1986, Dad had the only rights to the enterprise, Uni-Bend Engineering. The cellar of the outdated mill was the place I acquired my first expertise of what he did for a job. I used to be his first born, and would spend plenty of time with him, in my first 4 years of life whereas he was in that outdated mill. There have been instances after I had measles, and my mum nonetheless needed to work, so Dad would take care of me on the workshop. We had a big Alsatian and a pet pigeon, (recovering from a damaged wing) which lived within the workshop, so there was lots to maintain me occupied.”

Ben continues, “I keep in mind one in every of my favourite methods to go the time was to roll round on his large workshop flooring utilizing his chalks to attract footage on the most important canvas I had ever skilled. I had no thought what dad was doing or how nice of an empire he was a part of. Dad would typically be making footrest/rearset kits on his lathe, utilizing drawings and jigs he’d bought off Service provider and Durward.” Ray had additionally bought a unique workshop, one which began life within the 1850s as a coach home for a horse drawn carriage service. This was a constructing that, throughout the Seventies to the Nineties, had been owned by Ray’s good friend the place he saved classic bikes and vehicles. As soon as in Ray’s palms, the area was a greater match for Uni-Bend than the cotton mill cellar. However it all led to 1997 when Ray crashed at Olivers Mount. “This was devastating for the household and for the enterprise, and an emergency assembly was referred to as. It was determined that the one approach to save each companies could be for Grandad to promote his half of Unity and take over the working of Dad’s engineering firm. Grandad had positioned many of the orders with Dad and was the one one who knew each what was on order, and likewise knew what to do to make the orders. So, Grandad offered his half of Unity Equipe in September 1997 to John Newby’s girlfriend. And my mum signed all of Dad’s enterprise over to Grandad.”

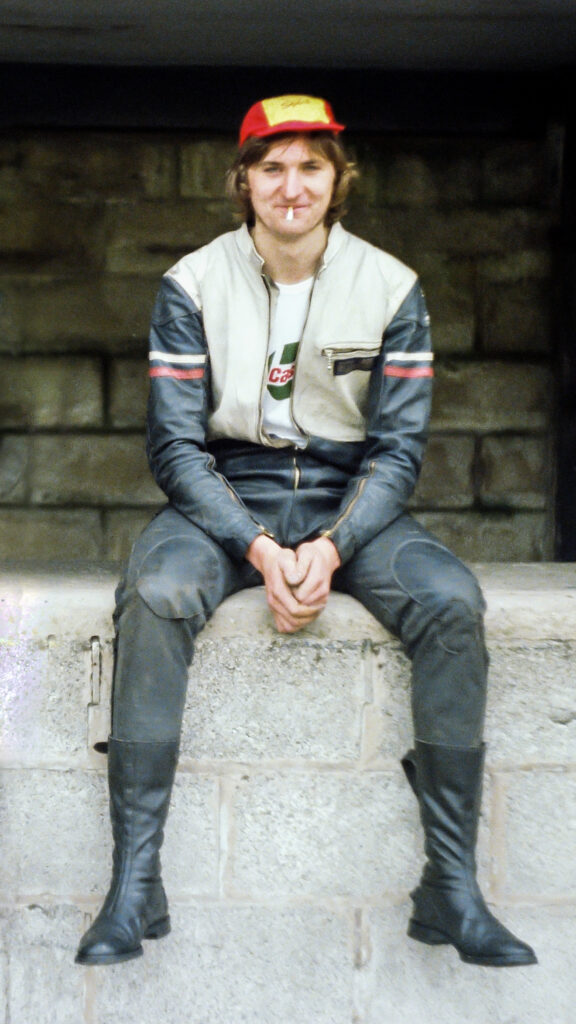

Peter ran Uni-Bend Engineering for an additional 10 years, then handed it over to one in every of Ben’s uncles. This, Ben says, was not scenario, because the uncle was solely in making the rearset kits, and never the exhaust techniques. He was to pay lease to Ben’s mother, however when he started to falter on funds to suppliers and on the lease, the household grew involved. “The ultimate straw got here, once we came upon from one in every of his pals, that he was making an attempt to promote gear out of the workshop. I flipped after I heard that information, and instantly requested my mum for the spare keys for the workshop. I went down that night and adjusted the locks. It was at that time that my mum mentioned, ‘Proper it’s all of your accountability now.’ At 24, the identical age my dad was when he began, I had lastly turn out to be a person and was trusted sufficient to inherit all my dad’s belongings. It was a scary time, stuffed with journeys to the solicitors and so on. We needed to give my uncle every week’s discover to complete off his work, and we crossed our fingers that he wouldn’t take anything from the workshop. Grandad oversaw all of it, and as soon as that week was over, I used to be handed the keys. And my coaching began, as the brand new proprietor of a brand new exhaust enterprise, RAYSONS EXHAUSTS, named in reminiscence of my dad, Raymond John Hardman, who died doing what he beloved, racing his bikes.”

Ben discovered methods to manipulate steel at a really younger age just by working with the fabric. “I used to be fortunate sufficient to be surrounded by very expert engineers all my life,” he says. “We used to have a household joke, the place we mentioned, steel should be in our blood. However I came upon, throughout lockdown, whereas doing my household tree, that I got here from a household of foundry males. My dad’s grandad, who died within the conflict, was a director of his family-run iron foundry, which was arrange by his grandad within the 1850s to serve the cotton mills and stone/coal mines.” As Ben has mentioned, “I used to be introduced up in dad’s workshop, watching him make pipes and work on his race bikes. I picked up so much from watching, and as his first son, he would inform and present me all the things. And if I used to be bored, he would let me have free reign in his scrap bin, the place I’d acquire bits of steel, and whack them into any form I needed. I nonetheless have two items on my mantle, a automobile and a Mickey Mouse, that me and Dad made collectively after I was a younger boy, labored out by me, and welded by Dad. I discovered so much about how steel behaves, from whacking it with a hammer at an early age and I at all times say, I believe Dad taught me greater than sufficient, earlier than he handed away. One of many best expertise that each him and Grandad taught me, was how to attract. This has taken me all through my schooling and was my principal intention in life. Realizing my dad at all times needed the very best for me, I made a decision to go to college to study automotive design, and after I graduated, I acquired a job regionally working as a draftsman, at a laser reducing firm. I had at all times dreamed of creating exhaust pipes like my dad, however by no means thought it might ever occur. I used to take a seat there, daydreaming about reworking my expertise into one thing that was bike associated. I used to suppose, I understand how to develop giant ducting, cones and hoppers. I understand how to attract them out and the way they might be shaped and so on. however I don’t know methods to weld them.”

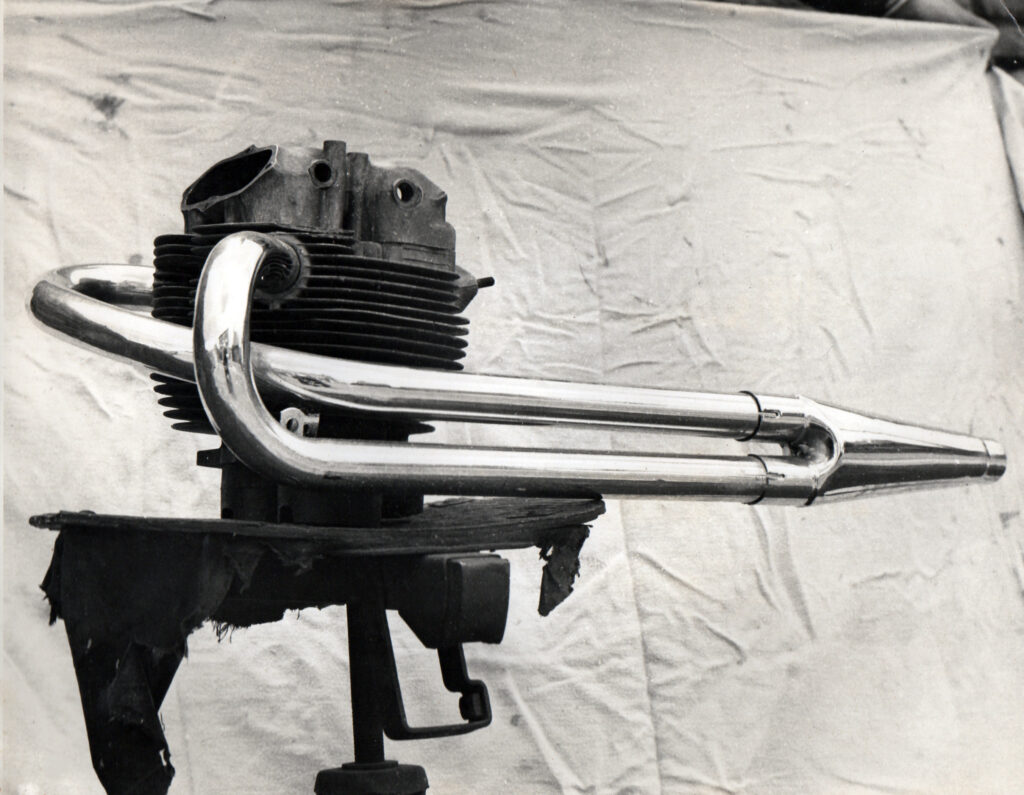

Till he was handed the keys to his dad’s workshop, and his grandad Peter spared the time to show him methods to create exhaust techniques. “Grandad taught me the standard means of creating them, utilizing solely hand instruments. Gasoline welding, brazing and sand bending. However now, I’ve additionally taught myself a couple of issues that neither my dad nor grandad might ever do. I discovered methods to make hydroformed techniques, utilizing the strain of water to type a curved cone. And through lockdown, I taught myself methods to weld aluminium. That means I can roll and weld my very own aluminum silencer our bodies.” Ben’s first jobs got here ‘from the household,’ and have been from his dad’s pals and his grandad, who had way back constructed up a reputation within the trade. “One in all my first correct jobs was making a street racing system for a basic Honda 350 K4. That bike had a household connection, because the engine had been tuned by my dad’s outdated workforce boss, and the client had come to have a set made to my dad’s dimensions, to match the tune of the motor. That was the primary bike I had out on monitor that had one in every of my exhaust techniques fitted to it, and to be displaying a few of my decals.” Subsequent got here a system for a CCM motocross machine, when the son of a former manufacturing facility CCM rider needed a precise duplicate of the pipe used on his dad’s race machine of the Seventies. “Off the again of that job, I’ve made round 50 extra techniques for CCM bikes. And the early Honda K4 job led to my pipes being fitted to seven-times Irish street racing champion Barry Davidson’s Honda K4.” In reality, it’s the racing techniques that Ben prefers to make, and his work has been fitted to a Basic TT race winner in 2023 with a pipe made for Ted Wuff’s Manx Norton. Ben says that ties in neatly together with his grandad’s Manx Norton historical past. He has additionally produced techniques for Norton rotary machines, owned by WizNorton, and raced by superbike rider Josh Brookes on the Manx GP. He’s additionally made small oil breather pipes to suit contained in the prolonged sumps on Yamaha R1 race bikes run by McAMS, an outfit Ben says is without doubt one of the prime groups within the British Superbike championships.

“A number of my repeat work comes from the race scene,” Ben says, “the place techniques are always being redesigned for further energy or want repairs or changing as a consequence of crashes. This is without doubt one of the principal causes I went down that route when beginning the enterprise, as there’s a regular stream of labor generated from it.” Customized work is one thing he enjoys doing, too, however he says it’s very troublesome to make a revenue on it, as a consequence of “all of the planning concerned. And when you make one mistake whereas making it, you find yourself solely breaking even.” Ben prefers to make techniques in batches, each time potential, the place somebody approaches him with a special-interest machine he can use to type a sample after which construct 10 to 12 units. He additionally leaves it as much as the client to market the ‘further’ units. “Doing it this fashion implies that the one that arranges it, normally will get their techniques (one or two) free of charge, by promoting the others with a small revenue to different individuals. And it’s the easiest way for me, as I solely need to cope with one particular person, and I make all of the techniques precisely the identical, which helps pace issues up. They’re the one jobs the place I make a small revenue.” What Ben received’t produce are techniques for machines equivalent to Triumph T140s or Norton Commandos. Whereas he can construct them — and has the patterns his grandad as soon as used for the bikes — they don’t seem to be economically viable for him to create. He can’t compete with less-expensive techniques for these machines being offered on-line. Ben provides, “These price the identical to purchase, as what it might price to get one chrome plated. That places me out of that market immediately.”

As to what the long run holds for Raysons Exhaust, Ben stays optimistic and opined concerning the rise of electrical autos. “I’m all for them, I’ve at all times been sooner or later, as a lot as I’ve been previously. However I don’t suppose the present plan utilizing batteries is the reply, and I don’t suppose they may kill off the petrol engine. As my grandad as soon as mentioned, ‘They nonetheless promote coal on the petrol station, don’t they!?’ I requested what he meant, and he mentioned, ‘No person ever banned the steam engine, it’s simply that the petrol engine was higher, and everybody swapped over.’ If electrical is best, then they may nonetheless promote petrol, like they nonetheless promote coal. The one drawback being that it’ll price extra, and solely the richer individuals will be capable of run petrol engines. For pastime functions, precisely the identical means during which steam engines are run at this time.”

He concludes, “I’ve determined to stay with doing one-offs. That means I can change the enterprise because the market modifications. I hope that I can keep within the classic market, as I completely love engaged on the early, uncommon bikes. As a result of they really are particular as survivors. I believe we’ll be okay and I hope I can keep within the classic market, being the one one to duplicate a classic system, utilizing the instruments they might have used initially. And if not, I’ll need to slowly begin making techniques for the following collectible bikes, which I’ve began doing extra of not too long ago. Making ‘70s 4-into-4 techniques and likewise copying Yoshimura model 4-into-1s from the Eighties, which I don’t thoughts doing because the bikes nonetheless fall into that competitors/particular class. And I at all times joke, that if the world ends fully, I can at all times set the enterprise up making safety railings/fences, to guard everybody’s property/retirement collections!”

[ad_2]