[ad_1]

Atherton Bikes nonetheless appears comparatively new, however the model is already 5 years outdated. And, up till now, it’s been making frames utilizing an additive manufacturing processes, therefore the AM tags. Throughout that point, it has refined the manufacturing course of a good bit and grown an ideal fame for its distinctive carbon-tubed AMs that now span from a 130mm path bike as much as a 200mm journey, a number of World Cup-winning, DH bike. Charlie Hatton additionally gained a World Championship gold medal on one.

Neglect welding, the Atherton S170 is bonded collectively identical to the AM170

All Atherton fashions thus far have been made in Wales and examined (largely by the household themselves) simply up the highway at Dyfi, the place they moderately conveniently personal and run one of many world’s finest bike parks. Preserving every thing native and in-house doesn’t imply the completed product comes straightforward although when manufacturing includes bonding {custom} spherical carbon tubes into 3D printed titanium lugs which can be laid down on a mega-money laser machine over sixteen hours.

The AM170 has 3D printed titanium lugs

And, if the laying layers of titanium powder half wasn’t time consuming sufficient, the lugs and {hardware} nonetheless require warmth treating and a number of hand ending with the bike engineers’ equal of dentist drills earlier than they will truly begin to bond a body collectively. In brief, this implies Atherton Bikes can at present solely produce 300 frames a 12 months with out investing in additional ludicrously costly Renishaw lasers. Who knew making {custom} bikes by hand in your individual facility with zero compromises would possibly show very time-consuming and costly?

The brand new Atherton S170 makes use of bonded alloy lugs and tubes to cut back prices

Atherton Bikes S170 have to know

- Frames optimised for power

- 7075 alloy tubes bonded to CNC machined alloy lugs

- New lower cost factors

- S stands for subtractive CNC machining course of

- 12 body sizes to select from

- DW4 suspension with 170mm journey

- Geometry designed round a 180mm fork

- MX wheels with Conti tyres

- Bikes assembled in Wales

- Three builds, and a body choice for £2,799

Enter the all-new S170. That is the model’s large mountain 170mm rear journey enduro bike constructed absolutely from aluminium. And it’s taken direct inspiration from the very good AM170 with combined 29/27.5in wheels I examined final 12 months. Utilizing aluminium as an alternative of carbon tubes represents an all-new method to make Atherton Bikes which can be cheaper but nonetheless sort of look the identical.

The machined lugs on the Atherton S170 give it a definite look

CNC machined lugs and alloy tubes

The ‘S’ mannequin achieves this through the use of a subtractive manufacturing course of, which sees the CNC’d lugs machined-away moderately than constructed up just like the additive titanium items that kind the joints of the AM skeletons. Machining the lugs with a computer-controlled cutter means Atherton Bikes can glue in spherical extruded aluminium tubes and keep 12 distinctive measurement choices and its distinctive body silhouette.

And the S170 undoubtedly shares a household resemblance, however the model defined the brand new manufacturing course of is about far more than simply appears. Bonding, as an alternative of welding, permits Atherton Bikes to make use of stronger 7075 aluminium that provides 70% larger fatigue efficiency and 70% larger final tensile power (UTS) than weldable alternate options reminiscent of 6061. One other advantage of bonding, is that it avoids heat-affected zones and potential distortions that may have an effect on tolerances and even geometry on welded aluminium frames.

Patent pending lug design

The model’s expertise with bonding sees the S170 use comparable hole double-lipped lap shear joints to the carbon bikes, however the precise construct course of is at present secret and the topic of a patent utility – presumably because of the ease with which rivals may ape the CNC mass-produced a part of the method extra simply than the fee/time restricted 3D printing technique used on the AM bikes.

Alloy tubes are bonded on to the lugs

When pushed in regards to the manufacturing course of, all I may get out of Atherton Bikes was that the body is evident anodised to withstand corrosion and the 7075 tubes themselves are plain gauge. Additionally the CNC-machined lugs are formed in a method that act like butted tubes and differ in thickness from end-to-end – in a lot the identical method a hydroformed tube has thicker materials on the ends of body members and is thinner within the center. Constructed like this, the S170 tube joints are moved away from peak masses too, ‘We use a CNC machining course of to create a localised monocoque construction. This optimises the burden of the aluminium, plus transfers the load from the tubes to the lugs in essentially the most stress-efficient method attainable.”

It’s not all made in Wales

So, the brand new aluminium body remains to be assembled in Machynlleth, however the recent materials crucially gives the power to massively scale manufacturing. With a brand new facility throughout city it’ll have capability for five,000 S frames/bikes as soon as working at full velocity. So look out for extra job alternatives the model is bringing to the realm. Initially there might be restricted availability of the S170 till the group strikes absolutely to the brand new website in coming months.

For the S170 Atherton bikes swap carbon tubes for alloy

Key aluminium items are machined abroad, and the model additionally confirmed us an enormous stash of 7075 tubing and the way the bonding course of is simplified and far faster on the S170. The S frames will include the identical diploma of high quality management, built-in-Wales stamped on them and must be as powerful as their carbon sibling with even higher affect and harm resistance on the tubes. Sturdiness is an enormous deal for Atherton Bikes and I used to be advised it’s a key precedence right here to supply a motorcycle that may roll with the punches and final for years with out smashing to items like too many frames they’ve seen demolished at Dyfi bike park since they opened.

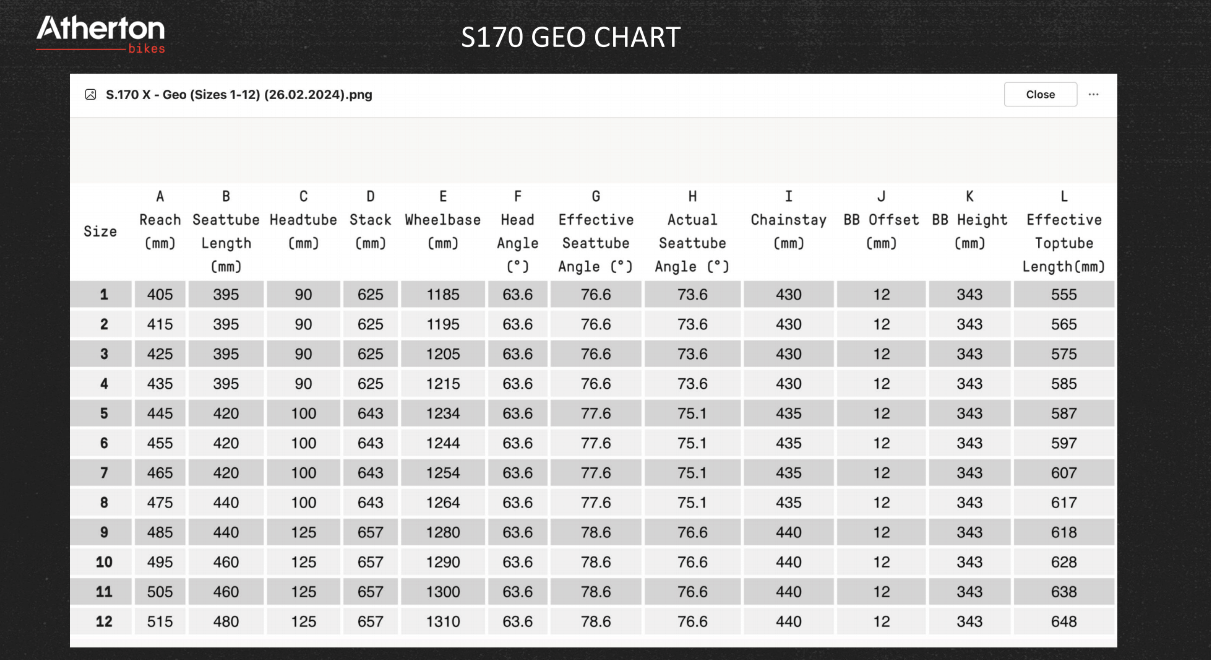

Similar geometry because the AM170

And, for the reason that S170 mirrors geometry and suspension data garnered from the AM170 and a lot of the plentiful sizing choices the place attain grows in tandem with seat tube angle, seat tube and chainstay lengths, journey and match must be completely sorted. And it doesn’t take a genius to see how the model may roll out this manufacturing course of to its DH and path bikes too, so watch this area.

Thus far, I’ve talked rather a lot in regards to the similarities between the brand new S170 and the unique AM170, however there are additionally fairly vital variations; not least a completely completely different suspension platform. The S170 will get Dave Weagle’s older 4-bar DW-Hyperlink design, moderately than the extra tuneable DW6 structure. There’s additionally the plain addition in weight with the fabric swap that sees the 465mm attain (measurement 7) S170 weigh a chunky 17.4kg on my scales, which is a kilo greater than the carbon model I examined. Light-weight carbon is clearly a part of this, however the precision with which Atherton Bikes can lay down the precise quantity of titanium wanted within the 3D printing course of can also be an element in comparison with the much less correct and heavier alloy lugs on the S170.

Twin-link DW4 suspension moderately than DW6

DW6 swapped for DW4 suspension

You don’t have to look too intently on the S170 again finish to see one of many key variations between what Atherton BIkes is asking DW4 and DW6 suspension is a triangulated aluminium rear finish, moderately than the a number of limbs and chainstay pivots on the AM170. This final half is a crucial side of most tuneability on the AM bikes, however provides complexity, further bearings and value. Engineer Rob Gow defined, ‘DW4 can provide the identical top-notch efficiency, however is cheaper, less complicated and simpler to keep up. The S bike was a whole evolution constructed off the AM170, so a number of the suspension high-quality tuning had already been accomplished and it was simpler to duplicate the numbers on the DW4 design to get near the specified efficiency right away.’

Glossy machining on the alloy swingarm

Flex engineered into the rear triangle

This uneven aluminium rear finish is manufactured abroad, identical to the CNC’d components and has been via quite a few revisions to try to match the AM journey really feel and flex traits. The most recent manufacturing model is kind of versatile to the touch and you may even twist the flat L-shaped seatstays slightly by hand, with the L-shaping presumably selling the specified journey really feel and likewise permitting rear cables to route hidden from sight. Beneath, there’s a thinnish rubberised chainstay protector, and the entire thing joins a posh machined BB part that extends down and forwards to cradle the decrease finish of the shock. The look of this half undoubtedly has a little bit of an old-school Iron Horse Sunday and even Large Reign vibe to it; unsurprising as each of these bikes used comparable brief twin-link suspension designs.

Potential stash field constructed into the top tube lug

Contained in the 7075 aluminium tubes, S170 cables are routed in quietening insulation and there’s a detachable cowl over the primary headtube junction which the model says will also be a miniature body stash sooner or later sooner or later (though it has extra to do with the manufacturing course of permitting entry to chop away most materials than accessing something inside).

Not as plush because the AM170

The unique AM170 was Dan Atherton’s pet undertaking to create a machine he can do-it-all on, and he’s additionally accomplished a number of the testing on the S170 prototypes which were floating round for a few years. Dan reckons with the geometry and sizing the identical, the one actual distinction is in suspension efficiency, and particularly, small bump absorption. The place Dan sees the AM170 as class-leading when it comes to monitoring and comparable with most DH bikes (I’d largely agree), the S170 is barely much less easy, which can be right down to supplies as a lot because the suspension design. He additionally reckons that when deeper into the journey, it’s onerous to inform the pair aside.

Different Atherton athletes and group members have had their enter too and the ultimate ride-tuned S170 chassis is out there as a body solely choice or in three completely different construct kits. Aluminium saves money, however being extra inexpensive than the completely custom-built AM fashions doesn’t precisely imply low-cost; the aluminium body alone is £2,799 (with a Fox DHX2 shock) and full builds begin at £4,799 for the cheaper RockShox Area construct, as much as £5,999 for the RockShox Tremendous Deluxe/Zeb/GX Eagle model I examined at Dyfi. There’s additionally a Fox Efficiency mannequin in between for £5,499, and all fashions use a 180mm fork and Conti’s newest tyres and Hayes Dominion A4 brakes that the race group use.

What number of bike manufacturers provide 12 distinctive sizes?

12 body sizes for the proper match

Twelve sizes are clearly rather a lot, however that’s nonetheless much less flexibility than the line-by-line customisation supplied on the AM vary. Additionally fastened S170 construct choices imply you may’t combine and match components or chainstay size to style both, like on the flagship AMs. Atherton Bikes goals to have some key sizes obtainable off the shelf in six months, and in case you’re questioning about twin crown compatibility on a motorcycle like this, the model hasn’t examined for it but, however appears prone to price it as soon as it will get the testing accomplished.

How the S170 rides

In order that’s all a number of details about the thought and tech behind this new idea, however how does it truly journey in comparison with the AM170? And, maybe extra importantly, the sort of long-travel enduro bikes from different manufacturers it’s going to be up in opposition to with a £6K price ticket. I solely managed about 5 runs at Dyfi in my restricted time on an early S170 with a few rogue components and wasted a piece of the day fidgeting with spring charges and suspension settings, so a full evaluation should wait till I get the bike again. I’m not paid to say ‘no remark’ although, so I’ll stick my neck out with a number of preliminary ideas.

First impression had been that the S170 wasn’t as plush because the AM170

Except for the geometry and steering, I’d echo Dan Atherton in regards to the similarities and likewise that the bike doesn’t have the last word smoothness of the AM. It additionally feels noticeably completely different to me to the AM170 when it comes to suspension help and rider steadiness/place (which possibly isn’t that shocking contemplating it makes use of a unique suspension platform and is made out of a unique materials and had a unique specification. The place the carbon bike has a smoothness that dulls most small bumps and vibration to make the bike tremendous calm, right here, it’s a lot sharper. The S170 nonetheless has the identical ‘trucking on’ speedy journey and balanced geometry to maintain the rider calm, however you may actually really feel what’s happening beneath on the wheels via the machine itself. In case you’ll indulge my first impression, it’s of a motorcycle with one thing of a race automotive really feel and being strapped right into a harness of an open-roofed Caterham or one thing bombing round with the wind in my hair and bum inches off the ground, moderately than deep leather-based seats and German-engineered ruthless effectivity of the AM170.

Total it’s a stable bike

One factor’s clear although, the S170 has the fundamental bones of a sorted bike with a singular look and manufacturing technique that probably gives real benefits. It isn’t gentle by any stretch, however holds good tempo throughout the bottom and by no means looks like a heavy outdated canine pedalling, using dynamically or when climbing. It also needs to be tremendous sturdy with these stable 7000-series tubes.

With a unique shock tune the Atherton S170 could possibly be higher

Atherton has in all probability accomplished extra S170 tuning and improvement with Fox DHX2 shock (the race group are on Fox and I’ve seen Fox package on Affy’s bike throughout improvement) and my sense is that this RockShox Tremendous Deluxe-equipped mannequin is probably overdamped, however that’s a straightforward sufficient repair, and, ironing out a number of creases was precisely the identical deal when Atherton Bikes first launched its AM150 5 years in the past. The model made the suitable delicate tweaks there and completely dialled these bikes in and might hopefully do the identical right here.

I’m going to go again to Dyfi for one more go on a S170 and can report again quickly with a separate full journey evaluation on whether or not this distinctive aluminium machine has the potential to develop Atherton Bikes into a very completely different sized proposition. Both method, the S170 is a singular engineering resolution and represents a brand new section for the Atherton masterplan that’s already having an enormous optimistic affect on this nook of Wales in a method or one other.

[ad_2]